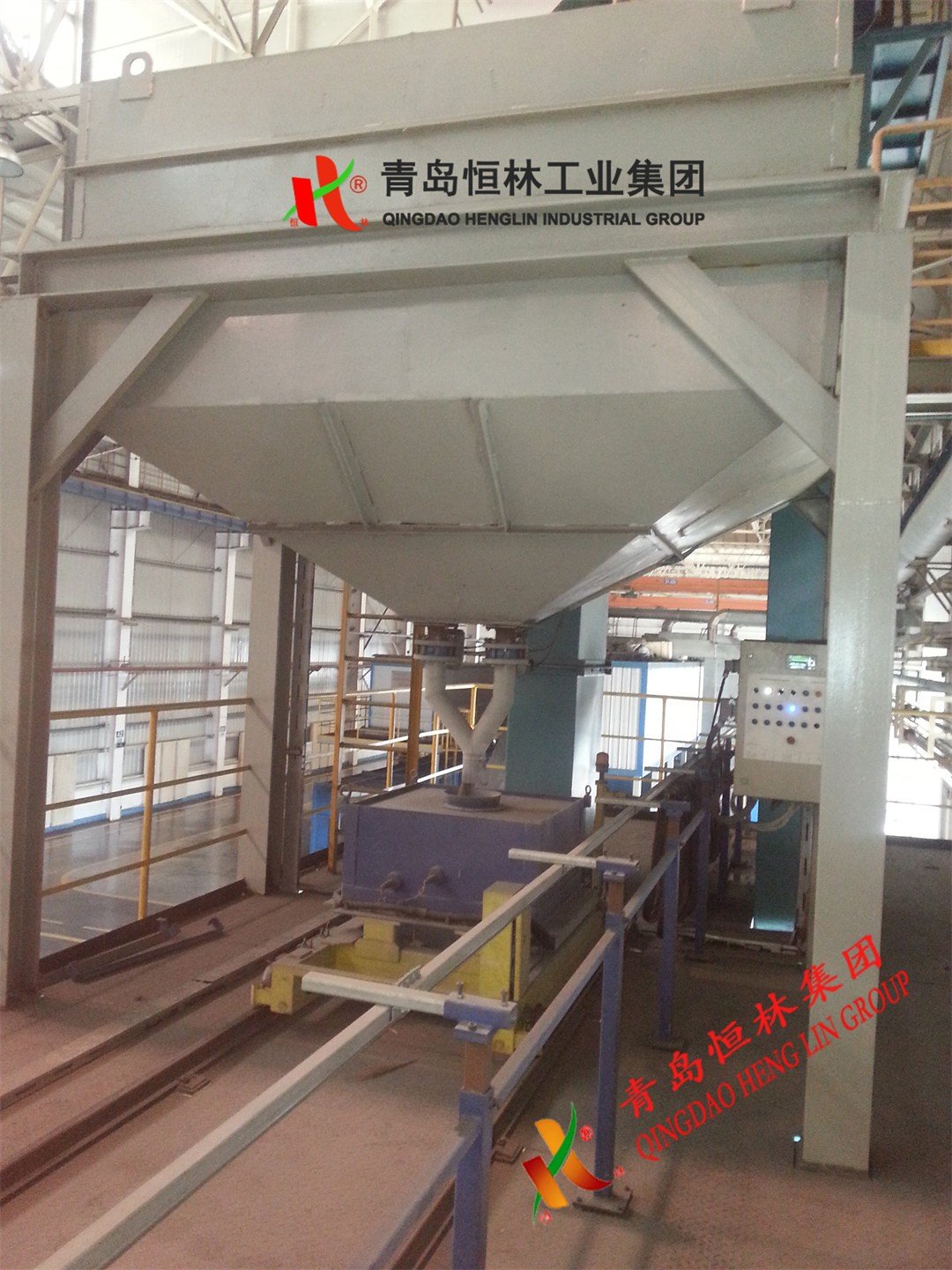

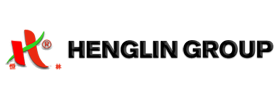

Cold box core machine and sand preparation working process

Hardening method: TEA Amine and CO2

Working table size: up to 1500*1000 mm

Driven Method: Hydraulic and Pneumatic

Electrical control: PLC OMRON or SIEMENS

Including: sand hopper heating system and Liquid material system(resin and catalyst) of sand mixer.

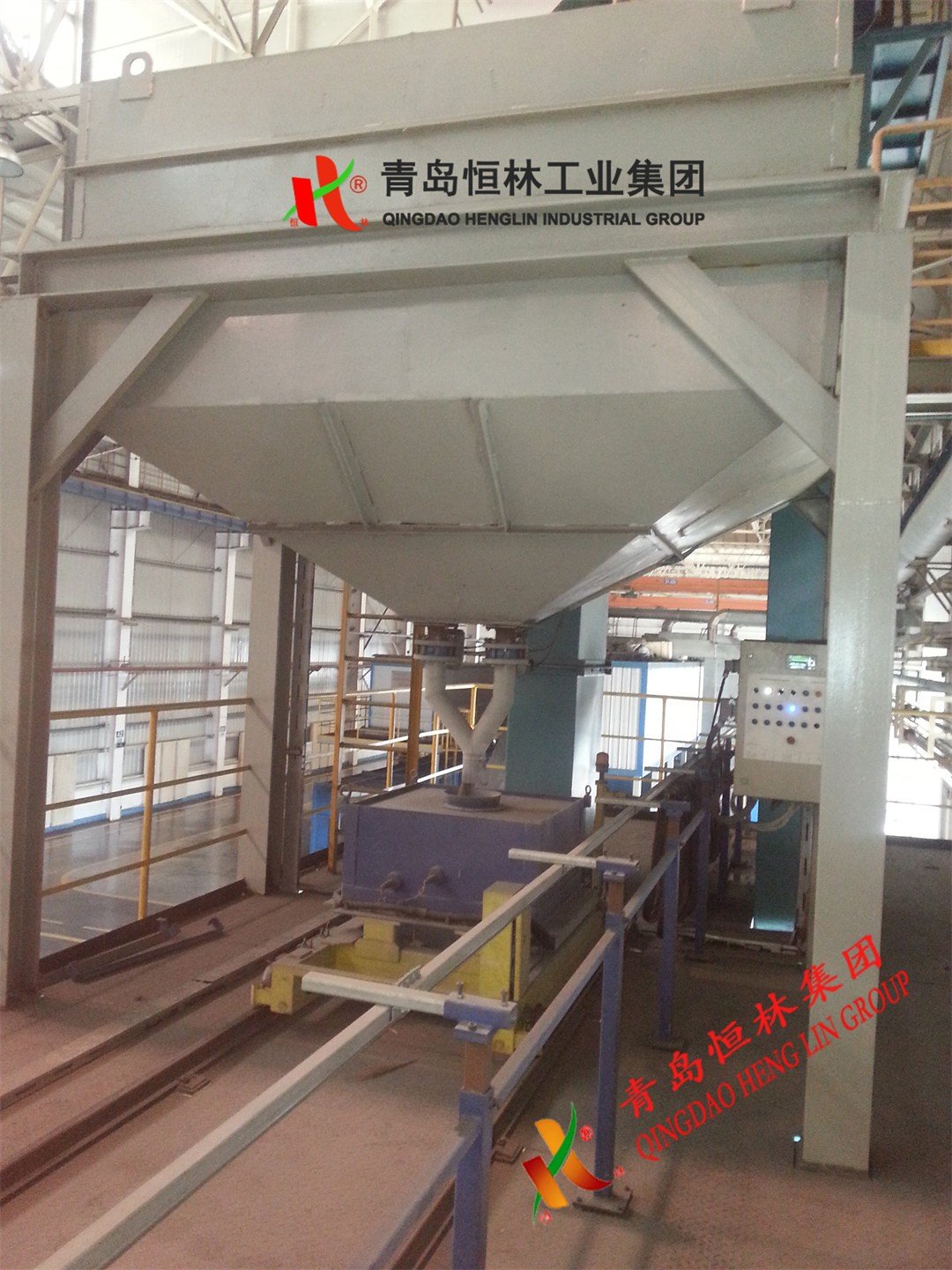

ZH860Y core shooter is consisted of body, column, beam, mold support parts, sand hopper, gas package and other component.

1. The body is made of section steel and steel plate welded.Sufficient rigidity and strength to ensure smooth operation of components.

2. The die cylinder is installed inside the body, the solenoid valve is controlled and the speed regulating valve is inside the body.

3. The control button plate is fixed on the left side of the bed, and the device is controlled by the programmable logic controller (PLC) when it runs in one week.

4. Four columns are installed on both sides of the bed to connect the bed, the necessary components of the beam. The four columns are welded with 180# channel steel, with higher strength and stability. Two working plates, four guide posts and guide sleeve are formed to connect the moving template with the clamping cylinder, and complete the opening and closing process along the four guide posts. When the moving die is in place, the four core posts can push out the core.

5. The cross beam parts are installed above the machine body. The top of the beam is equipped with a tight cylinder ejector, a gas storage tank, a walking cylinder installed on a column, and a gate at the bottom of the beam. When the sand tube moves left, the gate can be automatically opened for sand supply. The top of the gate is fitted with a sand stopper. It can automatically stop the inflow when the sand hopper is full.

6. Japanese OMQON (PLC) electric control system: It consists of electric box, position signal switch and control box. The electric box includes power switch, electric heating control element, program controller and so on.

The program controller is the core component which carries on the sufficient control to the entire machine. The electric control system adopts the imported programmable controller from Japan, and the integrated circuit is used in the system. The close switch is used as the signal element of the detector position. The switching current is provided by the switch power supply (made in Taiwan) in the electric box.

Operation Steps and Preparation:

1. Steps:

Mould closing →sand hopper in place→ sand shooter pressed tightly→ Sand shooting (exhaust) →sand shooter loosing→ sand hopper back in place→CO2 blowing head in place→ CO2 blowing head pressed tightly→blowing CO2→mould lifting→lifting core→finished and core taking