There are two kinds of sand reclamation method: thermal and mechanical type.

Project example:

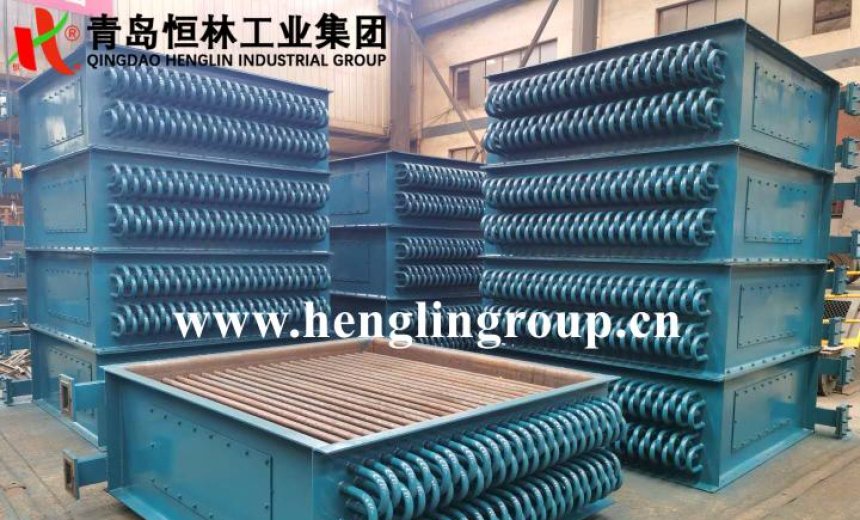

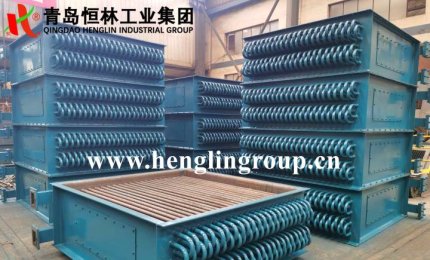

1. Using facing sand and backing sand mixing technology. The method of regeneration:The backing sand adopts mechanical regeneration, namely three-stage centrifugal regeneration + rubbing regeneration in series, and the designed productivity is 20t / h. The facing sand is regenerated by thermal method, namely heating and roasting, with a productivity of 2-2.5t/h.

2. Facing sand burning reduction: when the amount of resin added 1% -1.2%, cast steel <1.3%, differential content: 0.3% (below 200 mesh).

3. 2 sets of dust collector: 1 set for sand shakeout. Another is for sand crushing, mechanical regeneration and thermal regeneration. Dust emission: 15 mg/m3.

4. Sand reclamation equipment mainly includes: sand shakeout, magnetic separation, regeneration, dust collecting, PLC automatic control, etc. Including 2 times of magnetic separation, 2 times of screening, 1 set of mobile sand mixing machine. 4 sand hoppers of the sand treatment: Volume: 90+120+60+80/50=400T. New sand sand hopper volume: 50+3x30=140T.

5. The sand mixing machine adopts a 5t / h fixed sand mixing machine to make the sand core and a 20t / h mobile sand mixing machine. To make the sand mould.The sand hopper above the sand mixer is divided into new and old sand hopper.

6. Regenerated sand reclamation index: 85%.

7. The roaster is heated with gas. New sand is lifted by bucket elevator to the new sand hopper.