General Introduction:

It is mainly used for the production of ductile iron, gray iron and cast steel, especially for the production of high-grade ductile iron castings. It can be widely used in the mass production of automobile base support, differential housing, axle, brake disc, brake drum, exhaust pipe, camshaft, crankshaft, oil pump shell, gear box, steel track shoe, steel ball and other castings.

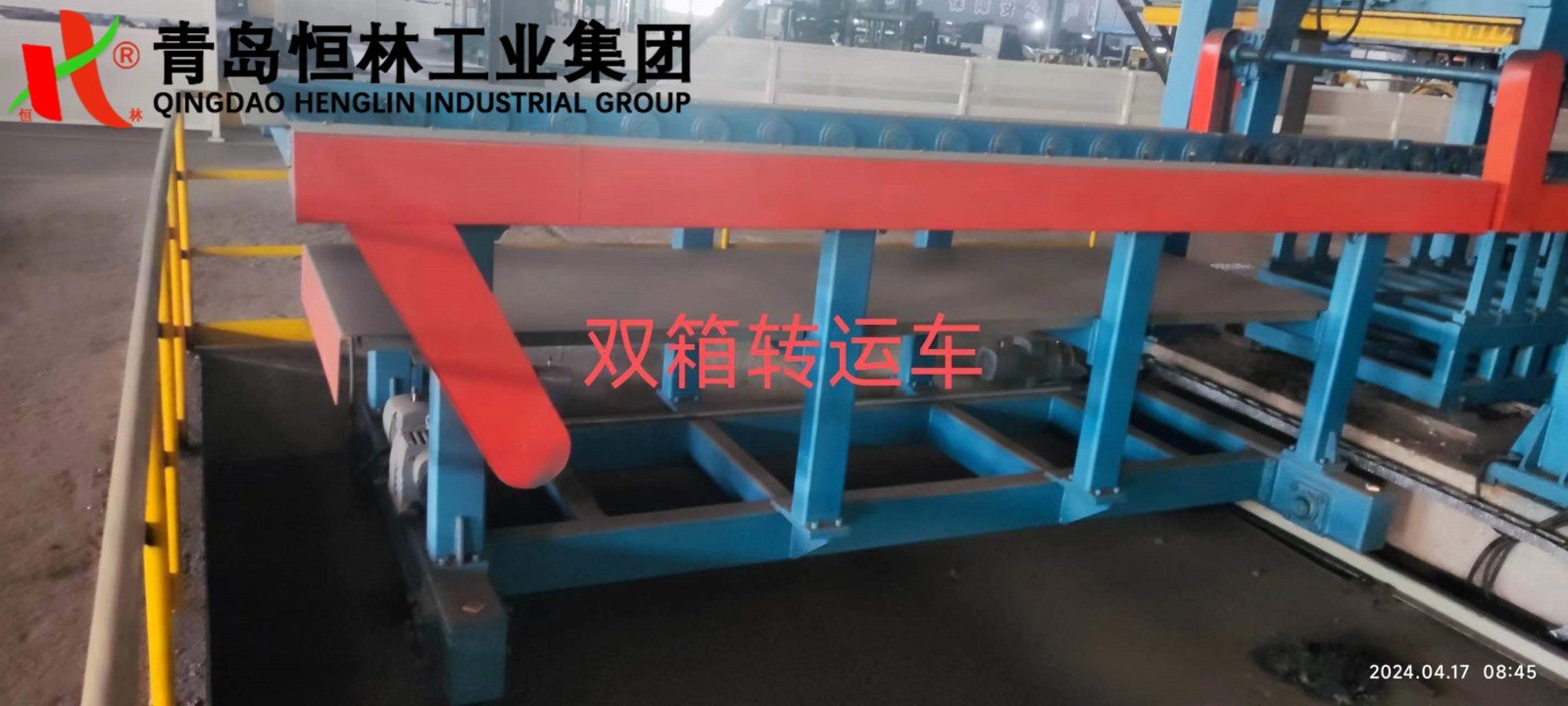

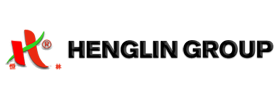

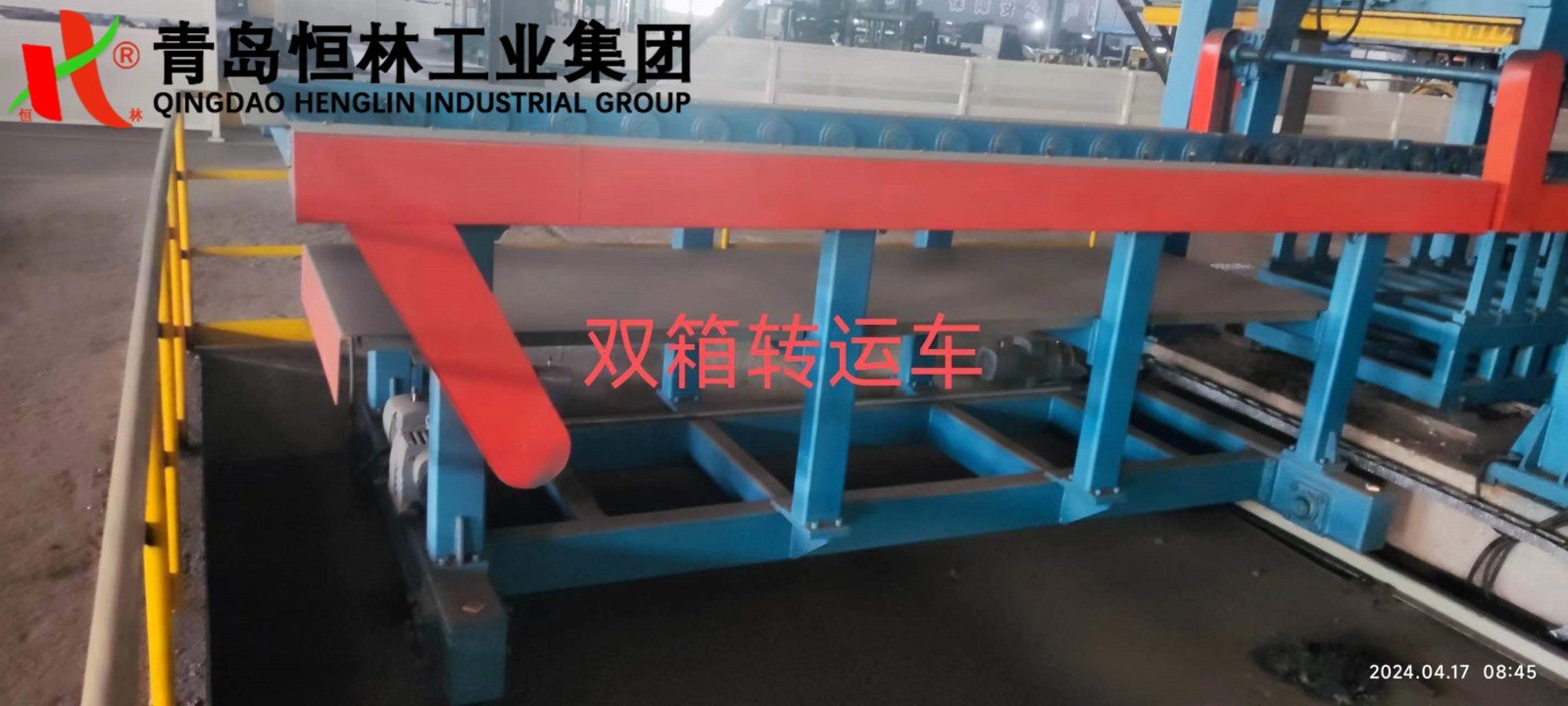

Working Process: sand molding—flask flipping and checking—flask closing—core setting— pouring—cooling—flask opening—flask rollover and castings out—cleaning flask—flask temperature adjustment—to the next cycle

Advantages:

The castings have the characteristics of,

1. High precision: To use phenolic resin coated sand to form the sand mold.

2. high finished surface quality : The casting is cooled quickly, so that the casting graphite is small, the crystalline structure is dense, and the appearance quality is good.

3. lower defect rates: Because the casting can cool quickly and crystallize quickly, there is no need for insulation riser and supplementary shrinkage riser

4. less consumption of casting material: Reduced the discharge of hazardous waste

Equipment operating environment temperature:-20℃~+50℃

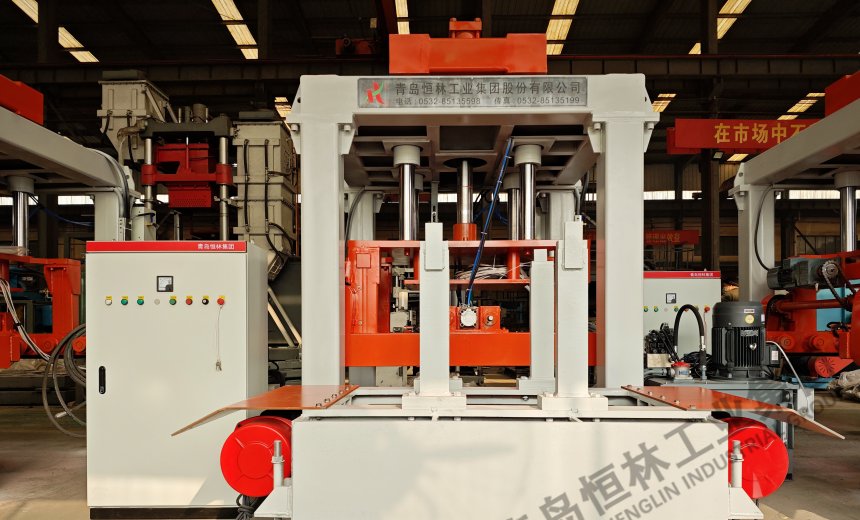

Productivity: 40-60 completed molds/hour

(1)Outer size of flask(Length*Width):850×850(can be designed as per customer's request)

(2)Pouring station: 22

(3)Cooling station: 20

(4)The central height of roller: 650mm

(5)Hydraulic pressure:10MPa

(6) Power:Three-phase five-line system;50HZ;380V;

(7)Compressed air pressure:0.5-0.6Mpa