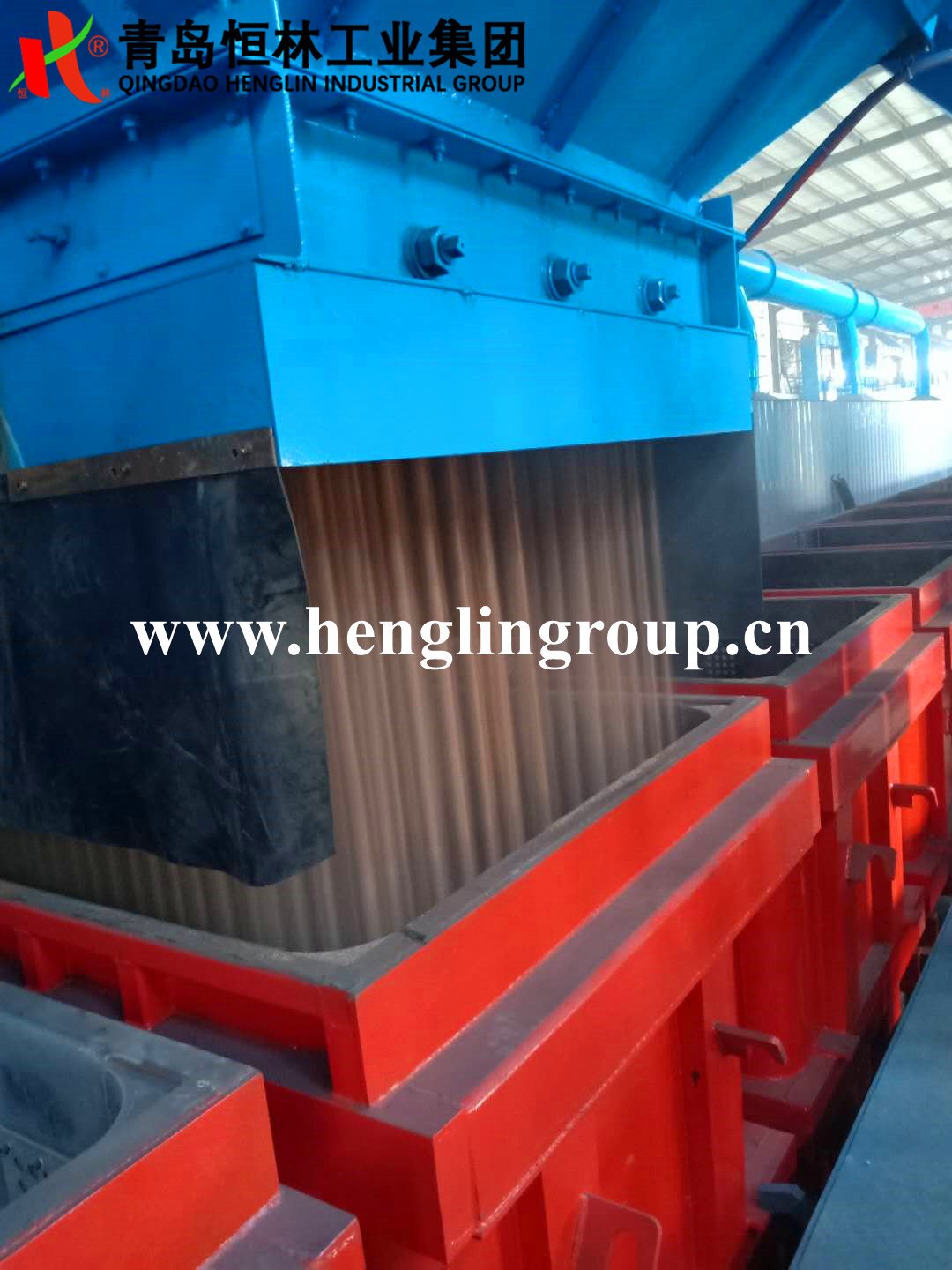

Lost foam casting (also known as full mould casting) is a casting process by combining the foam to the clusters which are similar to the castings, after refractory coating and drying, buries them in dry sand, pouring under negative pressure, evaporating of the model, liquid metal occupies the model position, and forming the casting after solidification and cooling. Compared with the traditional casting technology, the lost foam casting has the characteristics of good quality, high precision, low surface roughness, much less internal defects, dense organization, mass production, complex structure casting, low cost, can greatly improve the working environment, reduce labor intensity, reduce energy consumption and so on.

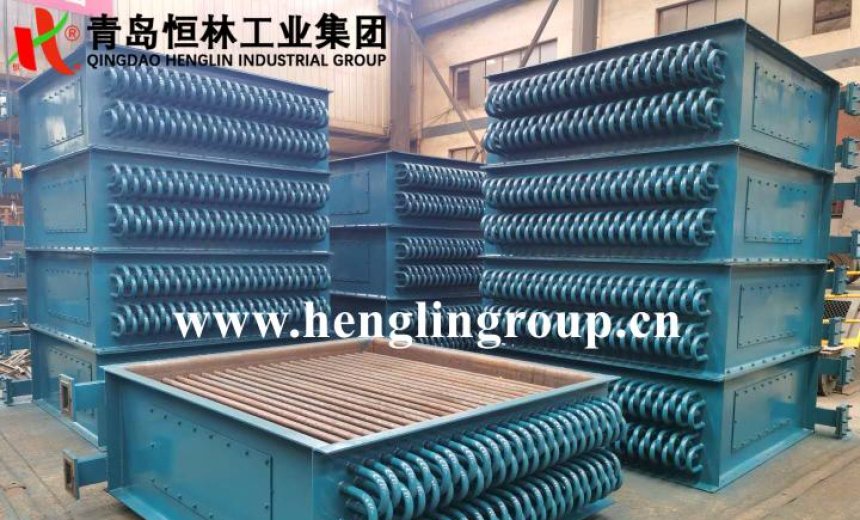

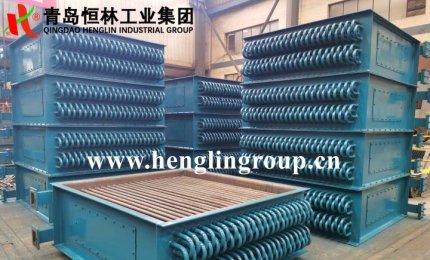

1、Sand reclamation capacity can be 10 T to 80T/ hour, sand secondary cooling, secondary screening;

2、Automatic control PLC whole line OMRON, touch screen, automatic fault detection;

3、Sand treatment adopts 2 sets of plate chain hoist with low failure rate and long service life;

All equipment vibration motor adopts Sino-German joint venture brand, bearing adopts Japanese NSK brand

NO. | NAME | QTY |

1 | Sand Plant | 1 |

2 | Vacuum Molding Station | 1 |

3 | Vacuum system | 1 |

4 | Dust collecting system | 1 |

5 | Flasks | 42 |