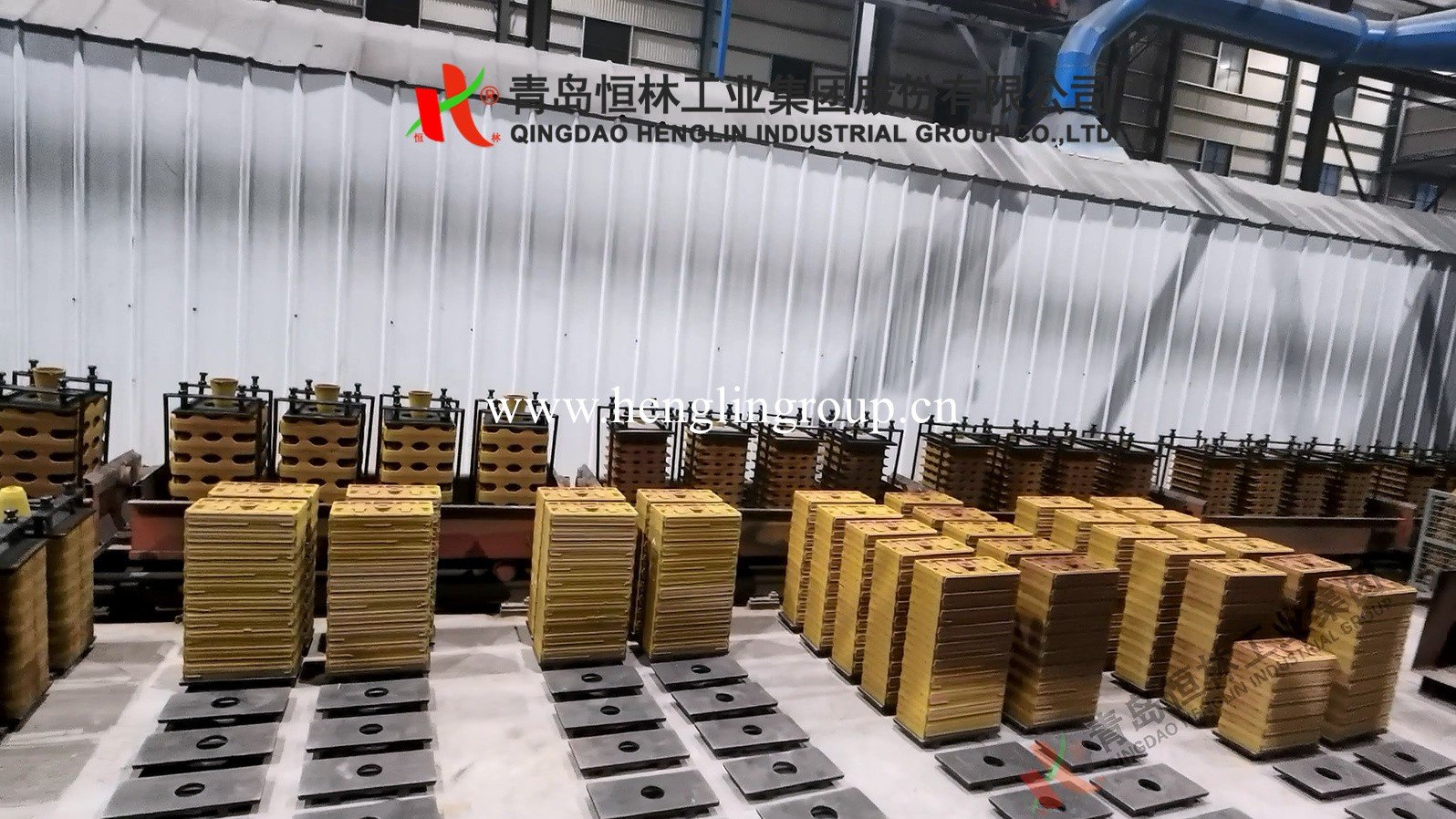

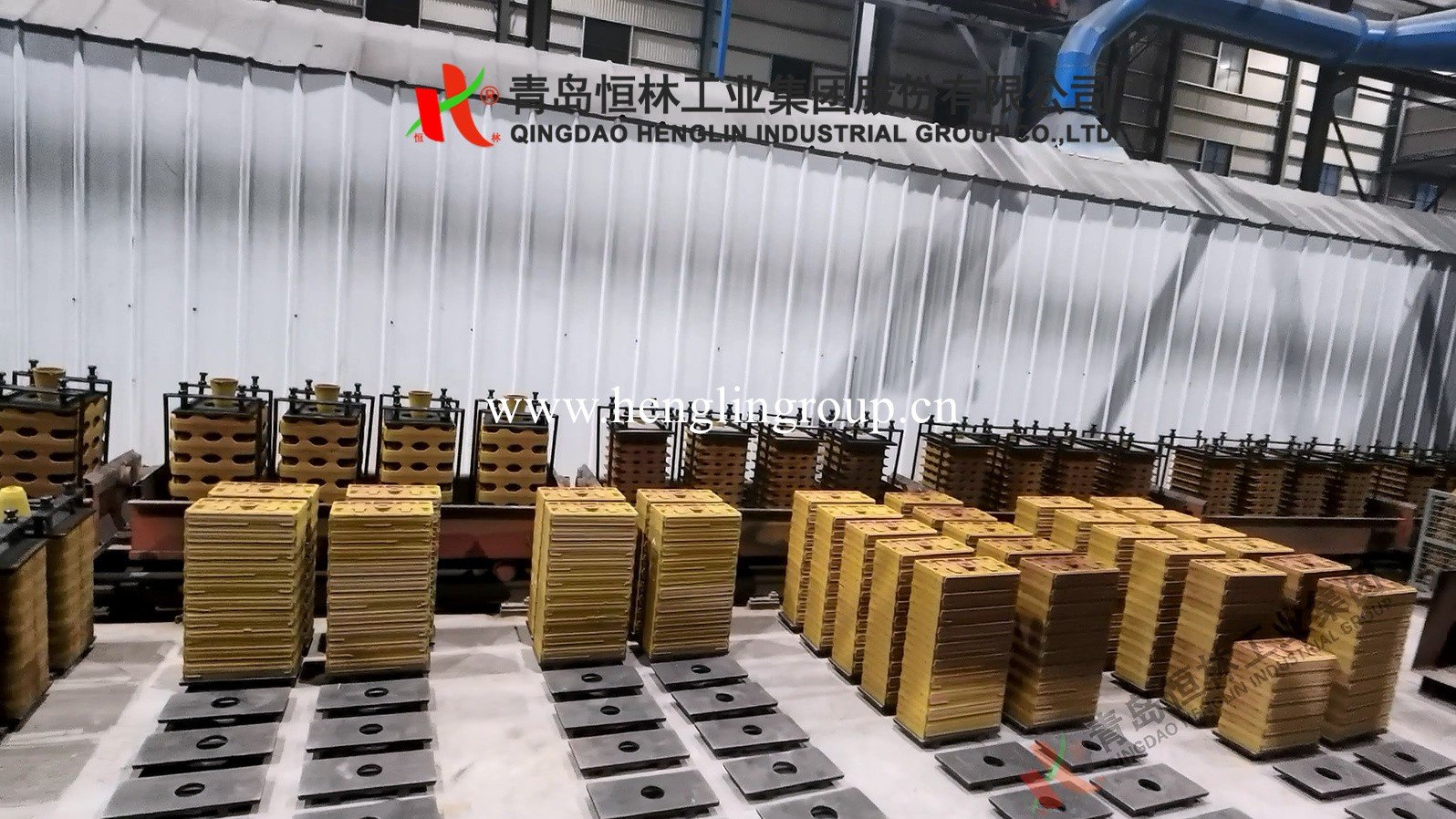

Coated sand shell / core casting line is mainly composed of automatic flask loading system, flask conveying system, pouring system, sand shakeout system, shot and sand separation and cooling system, electronic control system, hydraulic system, pneumatic system, smoke treatment system, sand shakeout and screening, dust collecting system, etc.

The main process is as follows:

the sand flask with cooling castings enters the flask turnover unit to do the flask turnover and sand shakeout, the hot old sand and shot enter the sand reclamation system, and the castings are taken from the sand shakeout machine and scale machine. The shots after the automatic turnover are separated from the coated shell through the vibration conveyor, plate chained elevator and automatic screening machine. The shots are sent to the sand hopper after cooling. The sand hopper is equipped with a material level sensor to prevent the overflow . Many pneumatic automatic sand adding stations are set in the molding sand hopper. The sand adding equipment is automatically expansion to avoid sand dust overflow. The sand adding inlet is equipped with dust collecting equipment, the dust collecting motor is synchronized with the sand adding, and the pneumatic automatic sand adding station completes the same function. The manipulator puts the sand flasks on the trolleys before the pouring process, the flasks with shells will be transported to the vibrating station to do the vibration after automatic sand adding finishes. The conveyor automatically pushes the finished shell sand mould to the pouring system for pouring, and the finished castings are transported by the ferry to the cooling station for cooling. It is the cycle of the molding line.

Content of the sand shell molding Process:

1. Sand flask conveying line

Automatic conveying line of sand box: including shell area, flasks flipping and sand shakeout area, pouring area and cooling area. It is composed of two transmission lines, two-end ferry car, electronic control system and [dust removal (gas) system]. The sand box operation system is fully automatic, controlled by Omron PLC, and equipped with touch screen display. The sand box adopts hydraulic flipping machine, with the maximum productivity: 30 boxes / hour.

1)Inner size of sand flask (L x W x H):1350x800x600 mm;;Pouring station: 12 .

2)Sand plant: 90 T

3)Bottom iron shots station:1, Top iron shots station: 1,Shell assembly station: 4,The production beat is approximately 1.5 minutes / box. The design productivity is 30 boxes / h.

4)the temperature of treated iron ball is 90℃; the diameter of iron ball is ф 3~ ф 5 mm.。

5)The ferry is driven by frequency motor and the sand box is driven by reducer.

6)Electronic control system: PLC, proximity switch selected Japanese Omron products, frequency converter Japanese Mitsubishi. Other low-voltage electrical components use well-known brand Chint, overload protection, overheating protection, motor starting protection, protection against fault operation .

2. Iron shots separation line

The iron balls are cooled by the water pipe, and cool the iron balls to about 90 degrees. After cooling, the iron balls enter the next process for storage, transportation and circulation

Working Process:

The fully cooled sand box on the cooling line is transported to the flask flipping station, and the flipping machine automatically turns the box. The tipping mechanism is the hydraulic system to clamp the sand box, and the main hydraulic cylinder starts to act. After turning over, the flask, casting and iron balls enter the vibration conveying shakeout machine, and the hole is φ 30mm to realize automatic separation and conveying of the castings, waste sand shell.